The process of cleaning up a beach is slow and tedious, even for the most enthusiastic environmentalist. The first few hours might be fun as you eagerly pick up plastic bottles and feel your burlap bag grow heavier, but as the day drags on, it’s hard to not fixate on the obvious: most of this trash never needed to be created in the first place.

Over the summer I spent a week with The Ocean Legacy Foundation, a small Vancouver-based nonprofit, learning all I could about their marine debris collection and recycling process. We set up camp on a small island on the British Columbia coast called Nootka, a region that’s just as hard to get to as it is to clean up. Despite there being very few humans in the area, the beaches are littered with marine debris. Ocean currents transport plastic all the way from Asia, while aquaculture buoys and nets that break loose in storms are sprinkled across the shoreline.

The plastic problem is a global one, but our dependency on virgin plastics is also driving certain industries forward on a search for solutions. Creating a product from recycled materials is a challenge, but as consumers demand more options that align with their values, brands must keep up. Recycled materials are quickly transitioning from a nice-to-have toward a must-have offering for outdoor brands.

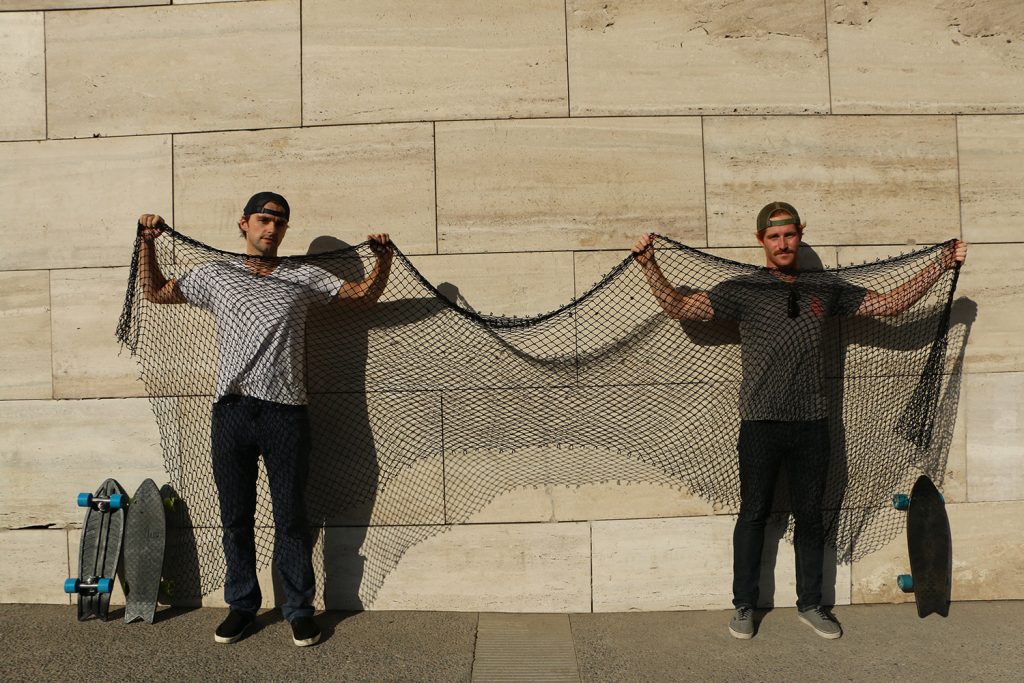

Half a world away from Nooka in South America, the recycling startup Bureo is turning fishing nets into recycled plastic pellets that can be used in the manufacturing of everything from sunglasses to surfboard fins to Jenga game pieces. Founded in early 2013 by three surfers who noticed a growing amount of plastic piling up on the beach, Bureo works with local groups in Chile to collect and clean discarded fishing nets, melting down the plastic into pellets that can then be resold to manufacturers across the world. Instead of recycling a wide array of plastics, the company’s tightened scope has allowed it to produce high-quality, recycled nylon at volume — essential to its goal of scaling to become an international supplier.

David Stover, part of the brand’s founding trio, believes solving the plastic pollution problem has to start before plastic enters the ocean. Brands and customers have a duty to invest in reusable products and recycled materials.

“But recycling plastic is easier said than done,” Stover explains. “There are thousands of plastic compounds, and the process for collecting, cleaning, and recycling each one of them varies — you can’t just melt down all the ocean plastic you collect and make ‘stuff.’”

The method Bureo uses to recycle its fishing nets is “mechanical,” meaning no chemicals are involved. The downside is that the color of the plastic can’t be modified. Other than this limitation – a flat black color – Bureo’s recycled nylon is on par with virgin nylon, offering the same hardness, weight and versatility.

That’s why last May, after three years of development, Costa launched the Untangled Collection, a series of sunglasses manufactured using Bureo’s recycled nylon. The Florida-based brand had found no difference between recycled and virgin plastic materials during their extensive product testing — according to the Costa team, the biggest challenge was actually sourcing the other components. Creating a completely recycled pair of sunglasses took an entirely new vendor base, with few recycled suppliers selling at the same scale as their virgin-material competitors.

With the Untangled Collection, Costa saw a perceptible uptick in sales and a wave of positive customer feedback. Retailers and journalists lauded Costa for its efforts. This helped land them larger partnerships, and open new accounts with Patagonia and REI. The brand aims to expand their recycled product offering this year.

Recycled nylon isn’t the only material that’s had a renaissance of sorts in the last few years. Outdoor lifestyle apparel brand Toad&Co has been progressively manufacturing more of its clothing line from recycled wools and yarns — their biggest leaps in progress have all come in the last few years thanks to improvements in quality and access to recycled materials from new suppliers.

Steve McCann, Toad’s Marketing Manager, said this has been the brand’s vision from the beginning. The company saw the apparel industry as wasteful and wanted to make a change. Their strategy was to fight the fashion industry’s throwaway culture, reduce waste in manufacturing, and provide customers with full transparency into their design process. The full Toad&Co line is now 100 percent sustainable, meaning that every garment they sell is made from a minimum of 80-percent sustainable fibers or fabrics that are third-party certified.

Toad&Co’s Material Manager, Ciara Cates, echoed the challenge I’d heard from others: finding the right network of suppliers that the brand can trust is difficult. There are many certifications and standards available; learning which ones to trust and adhere to is a moving target. Toad currently subscribes to Oeko Tex, Bluesign, and the Global Recycle Standard, using those certifications to stay responsible with wastewater and chemicals, because that is where most of the waste is created. As a company, Toad requires new certifications for every season and every fabric.

Like nylons, recycled synthetics are nearly the same quality as their virgin counterparts. Polyester is close, too. Others have a long way to go. Recycled yarn has considerable limitations — it’s larger, not as color consistent, and sometimes scratchier. Despite the challenge, the dividends pay off. Like Costa, Toad&Co has seen an explosion in demand for recycled products in the last couple years.

Patagonia was one of the first outdoor clothing manufacturers to turn trash into fleece when they began recycling polyester from plastic soda bottles in the early ‘90s. The outdoor industry giant, which already offers a wide range of products touting traceable and recycled down, organic and reclaimed cotton, and has made notable investments in recycled polyester, recycled wool, and recycled nylon, recently launched a recycled polyester GORE-TEX ski jacket and announced this month that all 62 of its water-repellent jackets will come from recycled materials.

Other companies are finding ways to cut production altogether. The rise of “repair culture” has more and more people opting to repair their worn-out clothing instead of replacing it. The Renewal Workshop is one of many small companies leading this effort, encouraging its customers to repair and extend the lifespan of a garment instead of relegating it to a landfill. Patagonia also offers repairs via its Worn Wear program.

While recycled materials can be difficult to create and source, more and more brands are continuing to step into the game: Polartec recently announced a fully recycled line, while the North Face announced their new Futurelight technology is made with recycled fabrics and leverages a production process that cuts chemical consumption. The new material is set to hit shelves this fall.

Images courtesy of Bureo.

XX Andy Cochrane